Here's the mold box getting started. I've just roughly lumped in the Kleen Clay to hold the part in position so that it is level in the box, and has enough space on all sides to make a good solid mold. I've tried to estimate a good volume of clay so that as I smooth it out the level will rise nicely to just below the edges of the part.

Using this set of tools:

from here (click on the "set of 12" thumbnail, it's the better set but has no direct link), I smoothed out the clay and worked it up snug against the edges of the part and the walls of the box. The RTV (Room Temperature Vulcanizing) rubber will work its way into the smallest spaces so a good seal is necessary. After that I built up the walls of the box with another row of bricks and laid in a thin snake of clay around the walls to raise the level a little more there.

Then I added one more layer of Legos so the RTV has enough space.

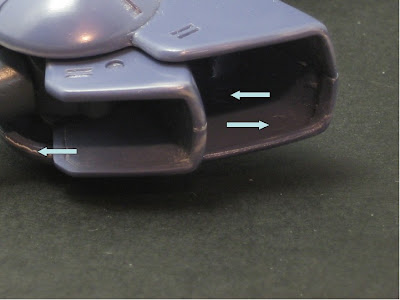

Here's the demolded RTV. I didn't use any mold release, which was fine in this case. I was nervous tho' because I did that by accident, not on purpose.

For the casting, I decided to use Bondo auto body repair filler. I was inspired to do this by a Brazilian figure sculptor on Hobbyfanatics named Ryuji who uses this stuff all the time. It's way cheaper than urethane or epoxy resins and the supply is much handier at the auto supply store (casting resin is a bit hard to find, even on the internet). I did spray mold release before spreading the Bondo into the mold.

The first one I did wasn't even worth showing because the working time on this Bondo stuff is only about a minute, which came as a big surprise and ruined the first attempt. This is the second attempt:

There are too many defects in this part to make it worth using on the final product, so I tried a few more times.

Here's what I came up with. The second and fourth ones are fine.

Now I just have to trim it up and smooth out the flat backside so I can fix it onto the flat foot and the prime and paint.

Wish me luck!

The underside, "before" on the left:

The underside, "before" on the left: